Standardized Modular LNG Plant

Achieve up to 44% savings by replacing diesel with LNG.

High IRR achieved with low CAPEX and OPEX.

Simple to operate and maintain.

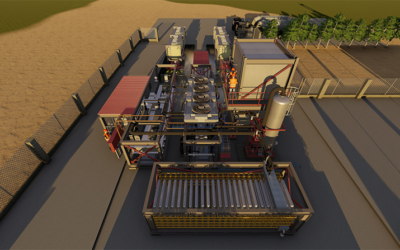

Plants can be combined, and relocated with ease.

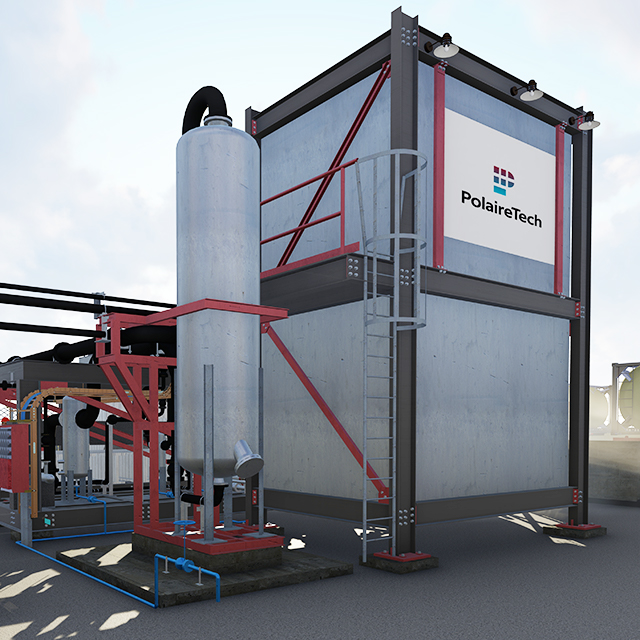

PolaireTech offers two standard modular plants, the Polaire P5TM and Polaire P60TM

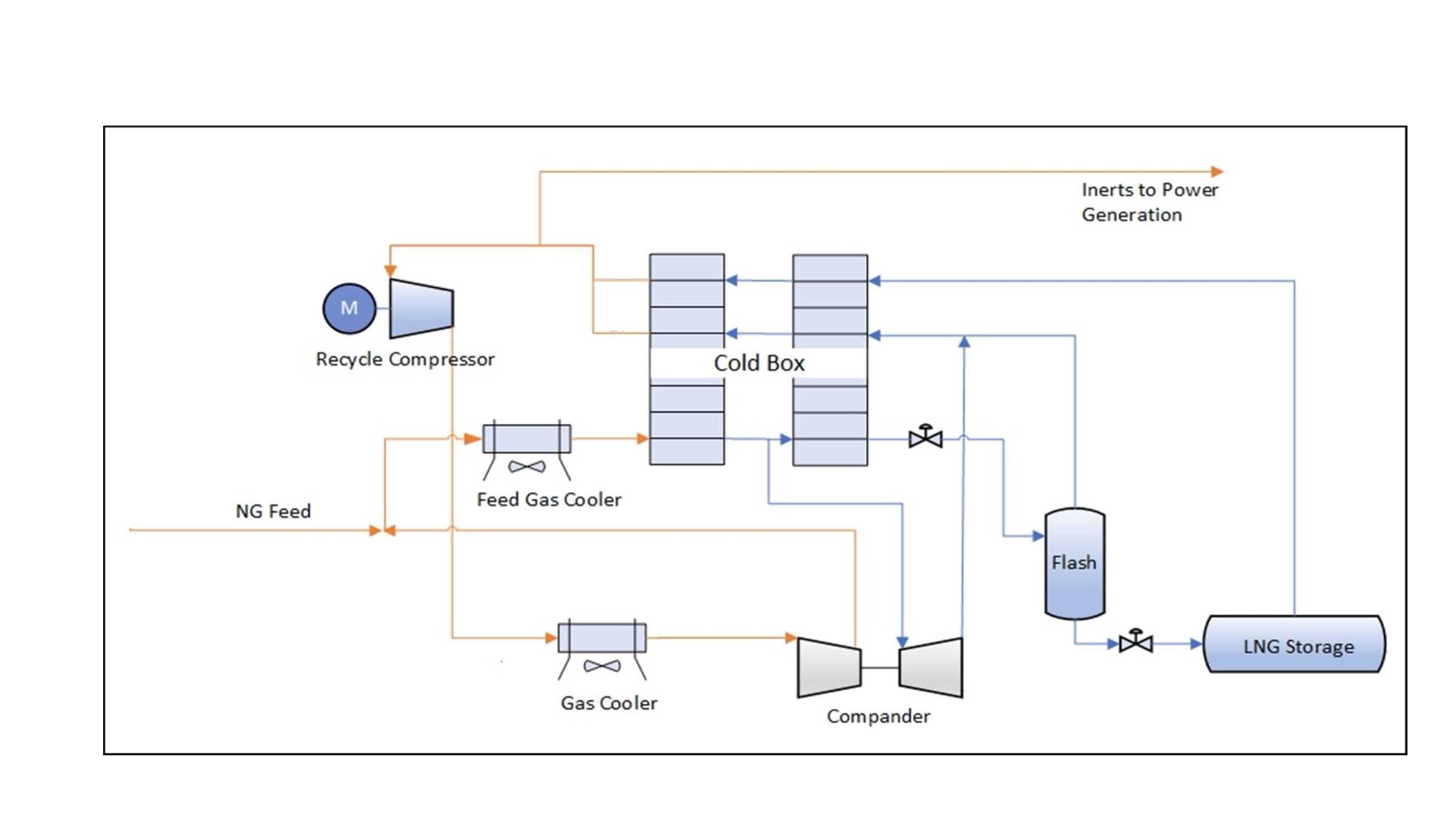

Zero Refrigerant advantage

PolaireTech is licenced to manufacture compact liquefaction plants using patented zero refrigerant technology up to 60,000 tpa natural gas capacity.

Within this license framework, we offer two standard small-scale LNG plants to match desired throughputs.

In response to the growing focus on small-scale LNG for peak shaving and transportation fuel, we’ve pioneered alternative small-scale modular LNG processes, departing from complex methods like mixed refrigeration liquefaction and amine gas treatment which are unsuitable for small-scale production.

Our optimised zero-refrigerant LNG (Z1-LNG) technology drives down costs by minimising equipment requirements and operational expenses.

- Inherently safer

- Fewer items of equipment

- No need for additional refrigerants

- High methane recovery

- Simple to operate

Standard Modular Units

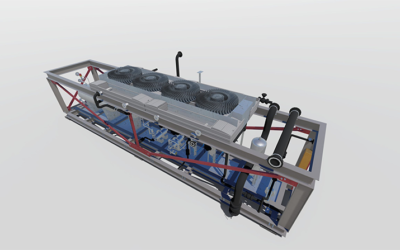

- Plug and play

- Standardised with a range of front end gas processing options

- Complete turnkey solution

- Short ramp up time

- Scaleable and relocatable

Comparison

Polaire P5TM

Modular plant footprint / size

12m X 13m = 156 m2

Equivalent fuel production / annum

5 000 ton LNG = 280 000 GJ

(6 181 ton Diesel = 280 000 GJ)

Cost saving by replacing diesel with LNG

Cost of 5 000 ton LNG: 280 000 GJ X US$ 17/GJ = US$ 4,76m

Cost of diesel equivalent: 280 000 GJ X US$ 35/GJ = US$ 9,80m

Savings: US$ 5,04m. (51.4%)

Exhaust emissions saved per annum

Polaire P60TM

Modular plant footprint / size

22m X 27m = 594 m2

Equivalent fuel production / annum

60 000 ton LNG = 3 360 000 GJ

(74 172 ton Diesel = 3 360 000 GJ)

Cost saving by replacing diesel with LNG

Cost of 60 000 ton LNG: 3 360 000 GJ X US$ 17/GJ = US$ 57.1m

Cost of diesel equivalent: 3 360 000 GJ X US$ 35/GJ = US$ 117,6m

Savings: US$ 60,48m. (51.4%)

Exhaust emissions saved per annum

Tons CO2 saved: 55 000 ton CO2

F.A.Q.

Frequently Asked Questions

What are the benefits of Z1-LNG?

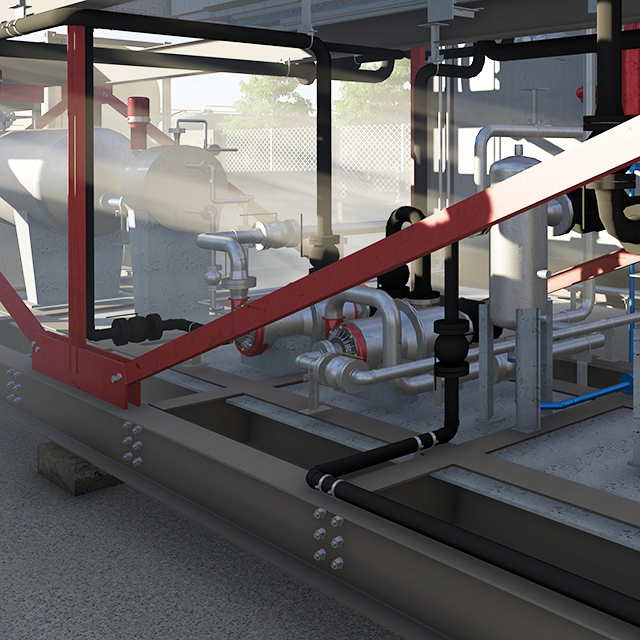

The Z1-LNG flowsheet uses methane as the refrigerant. As the heat capacity of methane is higher than that of for example nitrogen typically being used, the recycle gas loop is much smaller and thus the overall power demand is lower. As the methane cycle is inherently part of the methane loop no additional refrigerant storage or makeup is required. The overall liquefaction plant has significantly less equipment, requires smaller plot space, and has a lower capital cost than the competition.

What utilities or chemicals and catalysts do the plans require?

The plants are fully air cooled. Instrument air is required but is supplied on module. No catalysts are required. No make-up refrigerant or other chemicals (except oil) are required making these units especially suited for remote operation.

What other equipment and/or services do you supply?

Various supply options are available with the most basic option the supply of only the liquefaction module ex a module yard. The client will install the module and all the other equipment and PolaireTech will provide training and commissioning assistance.

A complete plant can contain in addition to the LNG module, a gas conditioning module, a feed gas compressor, a power generation unit, LNG storage and loading facilities, and a utilities module. These modules are optional, and the total scope of supply needs to be specified by the client. The modules and the required interconnects are all supplied on an ex-module yard basis.

What is the feed gas specification?

An LNG plant can be divided into two specific sections namely the gas conditioning section and the liquefaction section. Whilst the gas to the liquefaction section needs to be very pure (<0.1 ppm Water, < 50 ppm CO2, < 6% Nitrogen) the gas conditioning section needs to be designed to cater for the specific gas available on site.

There are three broad categories of raw gas available, being biogas with a roughly 50/50 mixture of methane and carbon dioxide requiring the most expensive gas conditioning section, unconventional gas (coal-bed methane, coal seam gas, biogenic gas) typically containing 90-98 % methane, 1-5% CO2 and 1-5% nitrogen, and lastly purified pipeline gas which it even purer. Any of these gas sources can be purified to the required specification.

Should the nitrogen be higher than 6%, the plant throughput and efficiency will be affected and will need a specific review on a case-by-case basis. Nitrogen can be removed through cryogenic separation, but it is very costly.

If components heavier than methane and a small percentage of ethane is present, these heavies (up to a maximum quantity depending on the composition) can be recovered within the LNG plant loop at very little additional cost. The Z1-LNG flowsheet of PolaireTech is specifically suited to remove heavies easily. The specific gas composition will need to be provided to assess the option.

Do you offer complete modules for gas conditioning?

Gas conditioning modules can be offered to suit the specific feed gas requirements. These modules are sourced from reputable gas conditioning vendors.

Plug and Play

Standardized

Short Cycle Time

Safer

PolaireTech: The home of small-scale LNG

Small-scale versus large-scale LNG plants

The surge in natural gas consumption, reaching record highs despite COVID-19, propels small-scale LNG plant growth. Contrasting large-scale facilities, these smaller counterparts offer modularity, quicker construction, and adaptability, revolutionizing gas transport from isolated sources. Understanding these distinctions optimizes LNG production in evolving energy landscapes.

Innovative standard modular small and micro-scale LNG plants utilizing zero refrigerant technology

Discover PolaireTech’s revolutionary small-scale LNG plants, leveraging the advanced ZR-LNG™ technology. These plug-and-play modules monetize local gas resources efficiently, reducing logistics costs. With lower power consumption and streamlined operations, PolaireTech offers a scalable, eco-friendly LNG solution tailored to diverse energy needs. Explore cost-effective and innovative LNG technology at PolaireTech.

LNG gas cleaning options

Explore efficient gas cleaning solutions for small scale LNG plants provided by PolaireTech. Learn about processes like mercury and VOC removal, heavy hydrocarbon and acid gas elimination, gas polishing, and nitrogen removal. Our in-house algorithms tailor solutions to specific gas compositions and site conditions, enhancing plant efficiency and equipment protection.